CAO (computer-aided optimization) and SKO (soft kill option) software was developed by Claus Mattheck at the Karlsruhe Research Centre in Germany. The CAO and SKO software works with FEM (Finite Element Model) used in engineering design. FEM is a numerical tool that breaks a component of interest into finite geometrical sections, then defines the material property of each finite element. FEM identifies areas of high stress, and shows the simulated effects of adding or removing material based on CAO and SKO.

Adam Opel, a part of General Motors Engineering Europe, used mostly the SKO to make car components lightweight but still strong enough to withstand stress. An Opel engine mount designed using the software is 25 percent lighter yet 60 percent more stable than one designed using the conventional design process. The engineers also used the computer simulation to configure other body and suspension components in the car, resulting in the car weighing 30 percent less, while maintaining stability, safety, and handling.

Daimler AG’s (formerly Mercedes-Benz) Bionic Car also used the CAO and SKO software to make the car lighter yet maintain its strength. More recently ,the software has been applied by designer Joris Laarman to the design of furniture.

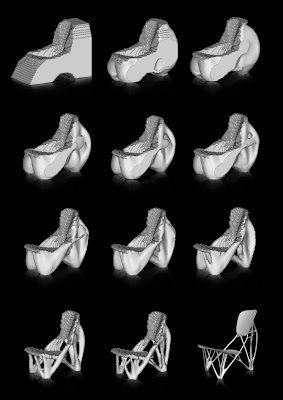

The transfer of technology between the natural world and synthetic constructs is at the heart of Laarman's Bone Chair, which is based on the generative process of bones. As bones grow, areas not exposed to high stress develop less mass while areas that bear more stress develop added mass for strength. Doing away with the superfluous results in an optimized structure that performs with the least amount of material. Laarman used the same 3-D optimization software to generate the form of his furniture rather than applying the software to a preexisting structure. As such, the Bone Chair moves beyond imitation of a biological structure to emphasize the implementation of a natural building process, suggesting that nature is the ultimate form-giver.

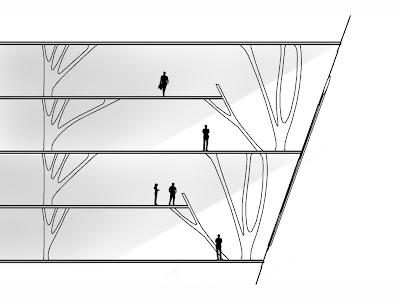

Quite suprisingly this technology has not yet been adapted to the construction industry. In the same way that the trunk of a tree grows to suit its conditions (the Seven Sisters Oak, a tree in Louisiana, had already stood 1'200 years when Hurricane Katrina hit and survived unscathed) the structural systems of buildings could be optimised to deal with directional wind loads, extreme weather, live and dead loads in a much more efficient manner.

I am trying to find software that I can download to experiment with but so far it seems that the high end software of Joris Laarman and DaimlerChrysler is kept very close to the chest. Other optimisation software I've found so far does not operate the way I need it to or is simply to complicated. None the less I propose the use of optimised structural column design in my project even if I am not able to realise an actual optimised form. I have sketched some ideas of columns whose shape responds to off centre loads.

References:

1. Baumgartner A., Burkhardt S., Mattheck C. The kill option: a powerful method to prepare engineering low-weight design proposals.

2. www.asknature.org

3. www.freepatentsonline.com